Solar Electricity Generation

Photovoltaic and solar electricity generation

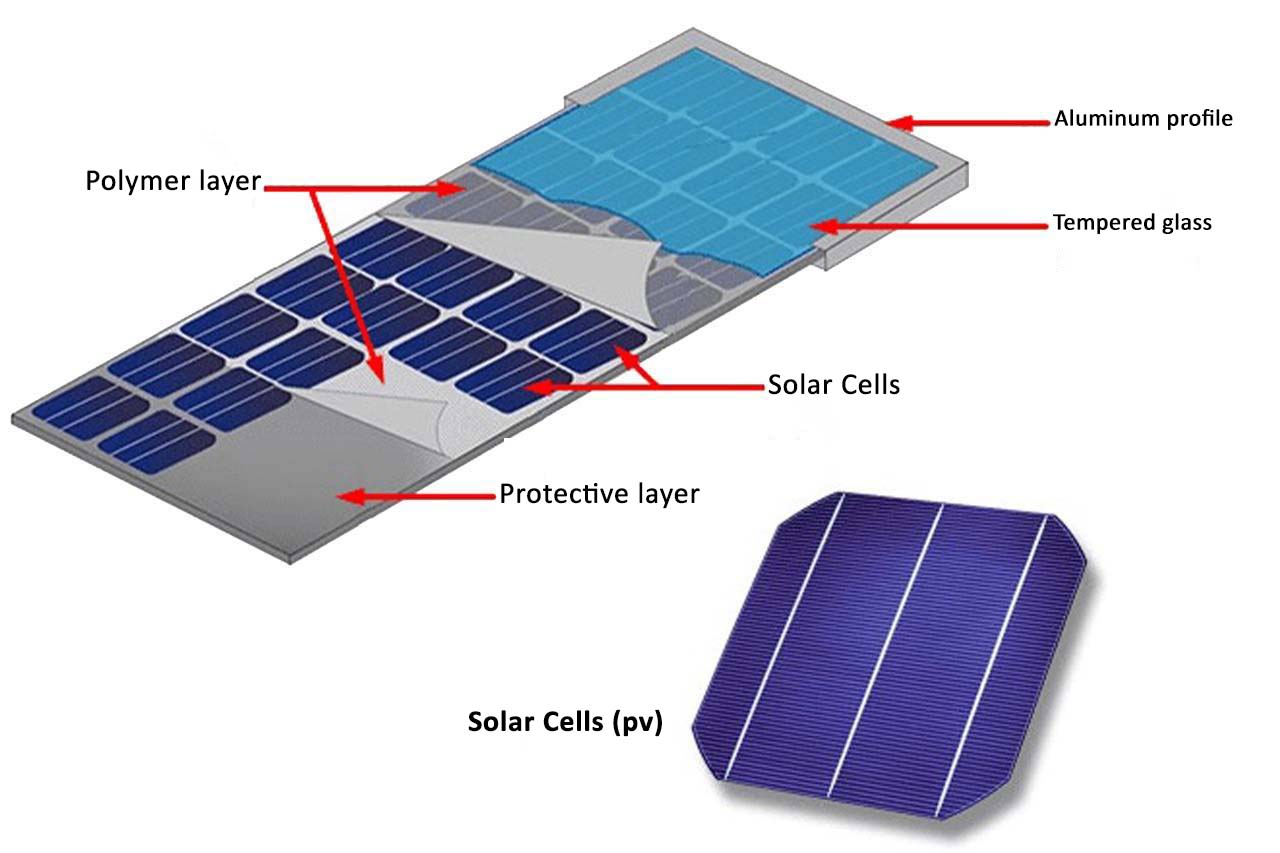

Solar cells convert sunlight directly into electricity. They are made of the same semiconductor material used in the computer chips. When these materials are exposed to sunlight, the solar energy splits electrons up from their atoms, and allows the electrons to move through the material and generate electricity. This process of converting light (photons) into electricity (solar electricity) is called photovoltaic (PV) effect.

But how do solar photovoltaic (PV) panels convert sunlight into solar electricity?

Solar electricity generation steps (Photovoltaic system)

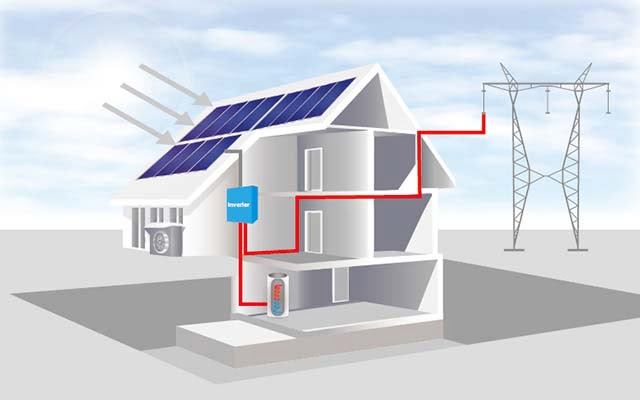

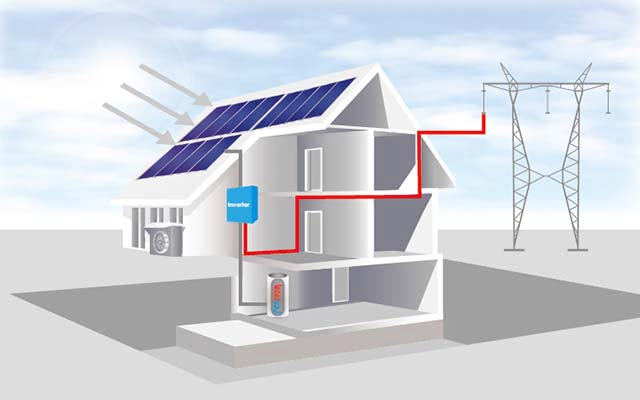

1. The solar panel absorbs sunlight, which causes the silicon cells to release electrons and convert it into direct current (DC).

2. An inverter device is needed to convert direct current (DC) to alternating current (AC) and make electricity usable for homes and businesses.

3. The generated solar electricity can be stored in batteries for use at night, or returned to the city grid and sold to the government .

4. If you ever need more electricity than your solar panel can produce, you can get additional electricity from the city grid.

The solar cells are combined into modules that hold 72 cells. A specified number of these modules form a solar panel. Several solar panels connected together can provide enough electricity for a house. Hundreds of solar panels can be connected to create a solar electricity plant for electrical or industrial applications.

Types of panels in the production of solar electricity

Since there are many space limitations and shading in any solar installation, PaidarSolar offers various solar panels and services to set up a solar utility on a domestic, commercial, or an industrial scale. There are two main types of solar panels used in solar utilities:

Monocrystalline and Polycrystalline

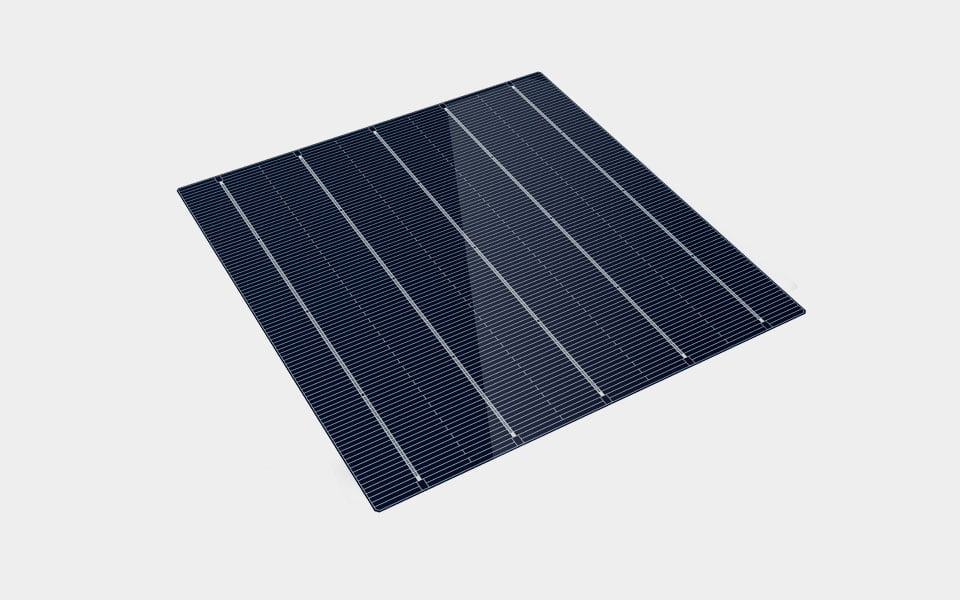

Monocrystalline solar panel

This type of solar panel (made of monocrystalline silicon) is the purest type of panels. You can easily recognize them by their dark appearance and rounded edges. The high purity of silicon makes this type of solar panel have one of the highest efficiency rates, the latest of which is more than 20%. Monocrystalline panels have high output power, occupy less space and have the longest lifespan. Of course, this means they are more expensive. Another advantage to consider, is that they are slightly less affected by high temperatures than polycrystalline panels.

Polycrystalline solar panel

You can quickly recognize these panels because these types of solar panels are square in shape with no cut corners and have a blue mottled appearance. Polycrystalline solar panels are made by melting raw silicon, a process that is faster and cheaper than monocrystalline solar panels. This production method has led to a decrease in the final price of this product, but it also reduces the efficiency of the panel by about 15%, as well as lower spatial efficiency and a shorter lifespan than monocrystalline panels are other features of this panel because they are more exposed to high temperatures.

However, the difference between monocrystalline and polycrystalline solar panels is not that great, and the choice depends largely on your specific situation. A monocrystalline panel offers a bit more efficiency at a slightly higher price, but essentially the same output power.